“TECNALIA develops AI-based digital tools to strengthen and preserve competitive advantage in the plastic parts sector”

TECNALIA and LARRAÑAGA PLASTICS have implemented an adaptive process control system capable of suggesting and modifying injection parameters depending on the supplied pellets

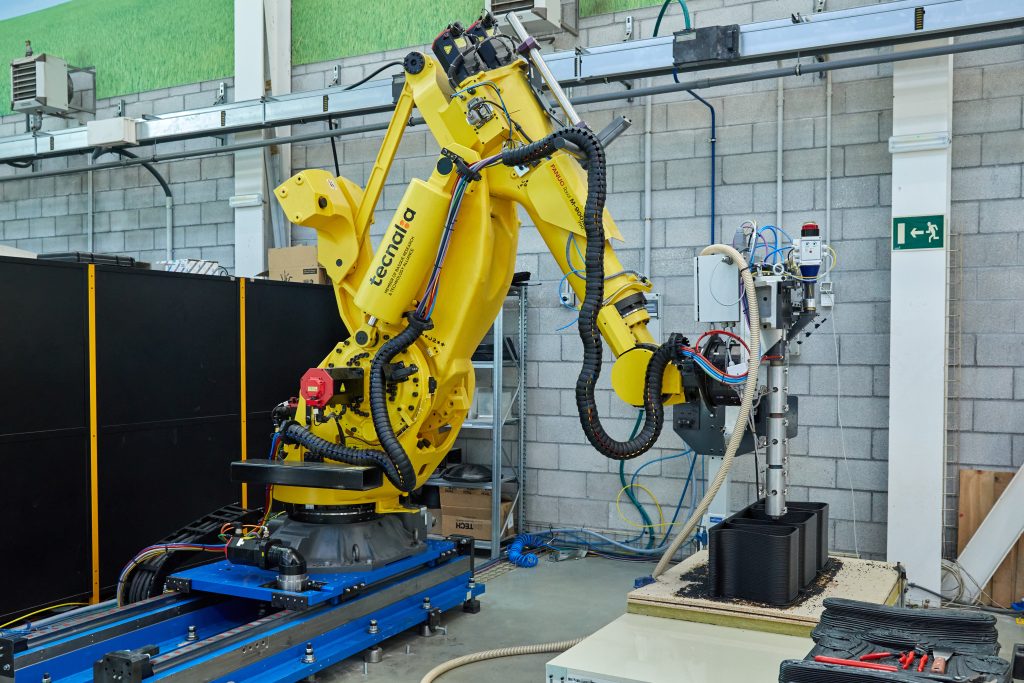

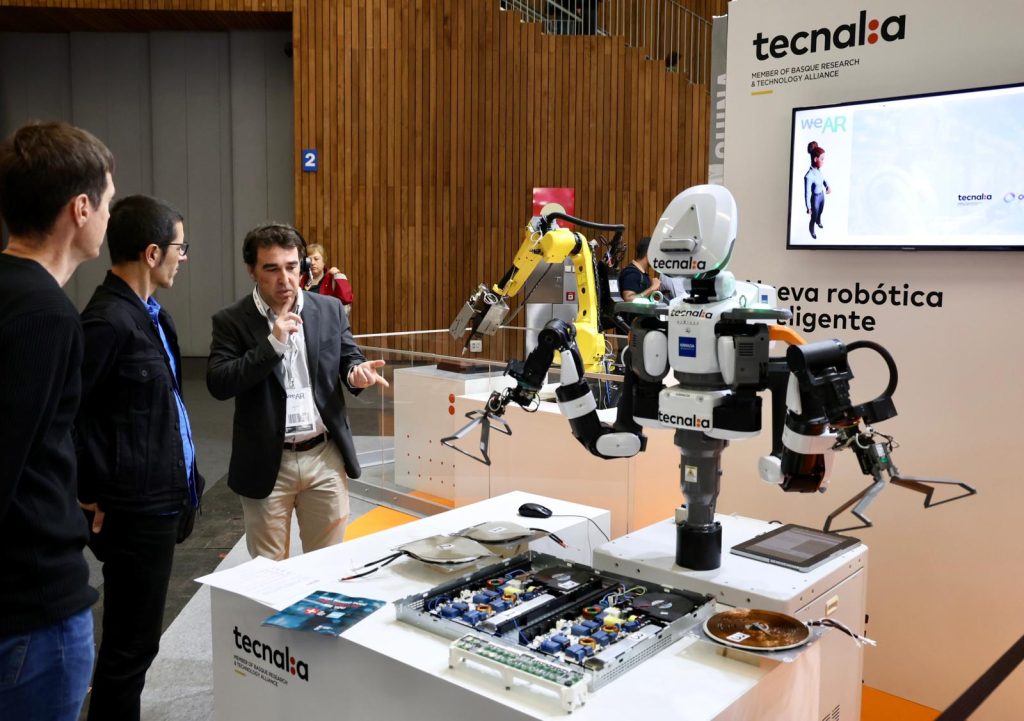

TECNALIA and LARRAÑAGA PLASTICS are developing digital tools based on AI to strengthen and preserve its competitive advantage, especially in its high-tech markets. The challenge lies in the implementation of an adaptive process control system capable of dynamically suggesting and modifying the injector’s control set points/parameters, depending on the supplied pellets, with the aim of achieving high-quality, zero waste injected parts.

In the process of creating the final technological solution, a reliable end-of-line system has also been developed and implemented with the aim of assessing many aspects of the quality of the parts: from visual and aesthetic to structural quality, by using sensors in the mould cavities.

This milestone does not mark the end of our joint progress as we continue to collaborate on more ambitious horizons, applying innovative AI techniques. You can read our full article in the Spanish Plastics Centre digital magazine.

Circular economy in production processes

In future years, the plastics processing industry will face a new, unknown scenario, mainly driven by the growing trend towards a circular economy in production processes. More environmental awareness and Europe’s strong strategy to use recycled polymers in injection moulded parts have prompted major automotive firms, for example, to include the use of significant amounts of recycled materials in their specifications.

- This new paradigm will force the processing industry to source recycled materials from a wide range of suppliers, which will presumably offer less homogeneous features, thus having an impact on operations.

- In addition, the higher cost of recycled materials, caused by low availability and complex recovery processes (mechanical and chemical recycling), will inevitably boost process optimisation to avoid increasing economic losses associated with waste and its environmental impact.