Laboratory for studying the microstructure of materials related to physical, mechanical and chemical properties and their thermomechanical history.

We carry out tests accredited under the UNE-EN ISO/IEC 17025 standard and have extensive experience in analysing different types of materials (metals, composites, ceramics, welded joints, etc.).

Description

The following tests/analyses can be carried out in the laboratory:

- Macrographic examination (welded joints, fibreglass welds).

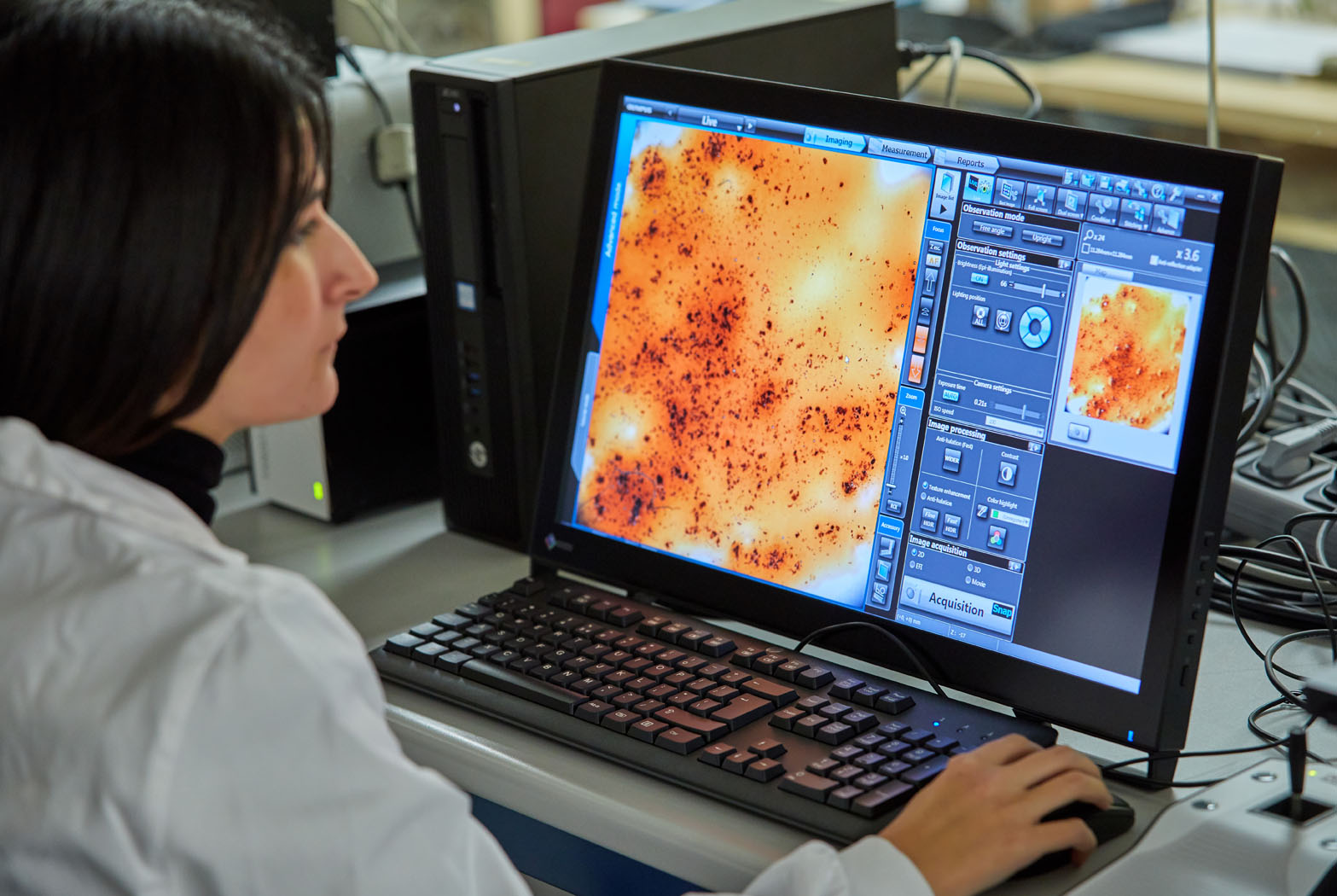

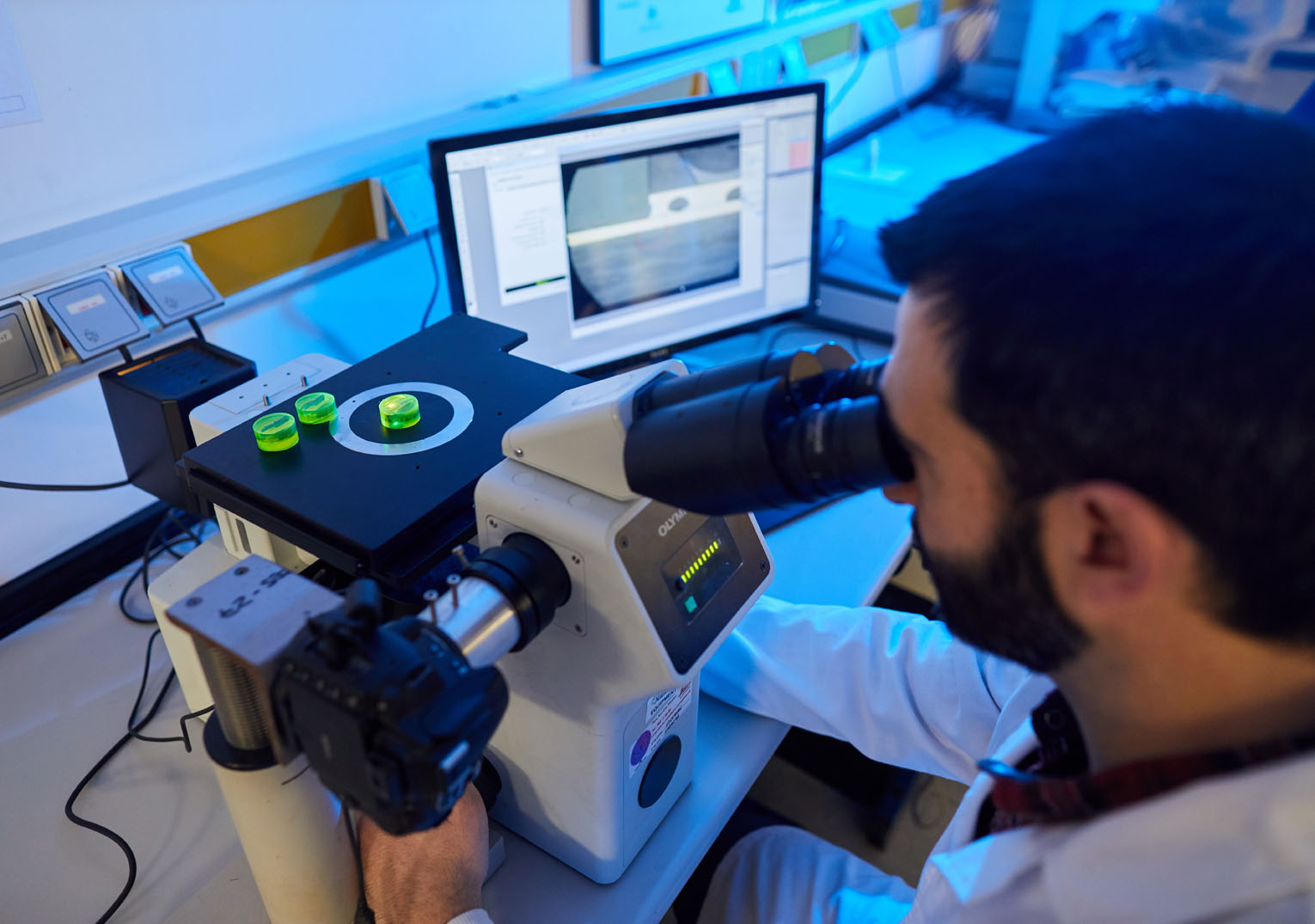

- Optical microscopy analyses of all types of materials (microstructures, grain size, determination of non-metal inclusions, coating thickness measurements, etc.).

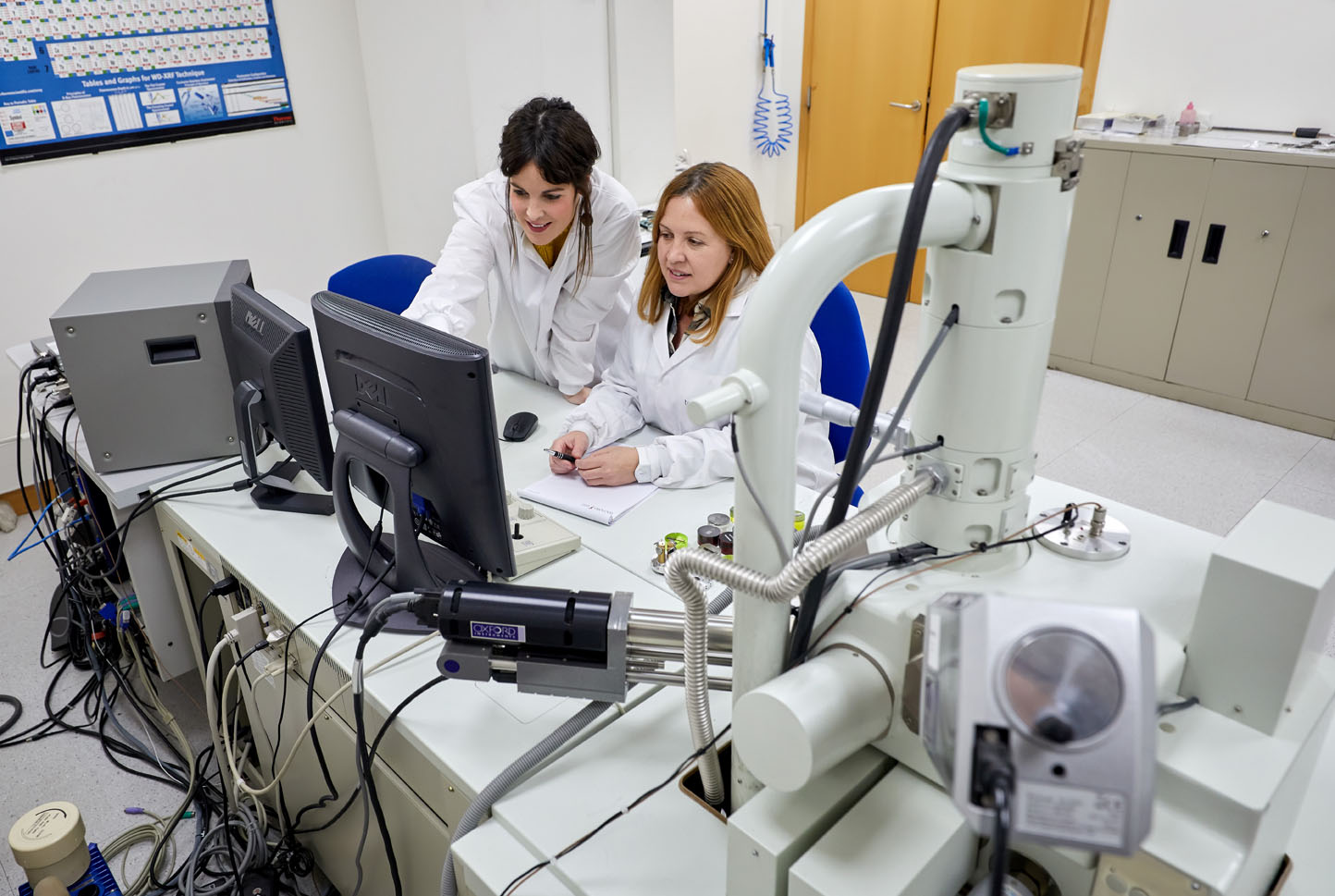

- Scanning electron microscopy (SEM) analyses, such as fractographic analysis, microstructure, defectology and identification of constituent materials using the energy dispersed spectrometry (EDS) technique.

- Identification of phases, measurement of residual stress, textures, layer measurement by X-ray diffraction (XRD).

- Vickers micro-hardness tests and determination of the depth of surface thermal treatment.

- Phase/particle quantification through image analysis.

- Micro-sectional analysis of joints.

The laboratory has the following equipment:

- Optical microscopes with integrated digital camera augmented up to 1000 times.

- Metallographic replication and residual life.

- Digital image processing software

- Manual, semi-automatic and automatic Vickers micro-hardness equipment

- Portable field metallography device.Scanning Electron Microscope with Thermionic Emission (SEM) and Field Emission Scanning Electron Microscope (FE-SEM) with EDS microanalyzers

- X-ray diffraction (XRD).

- Stereoscopic magnifier augmented up to 200 times.

Aimed at:

- Renewable energies

- Manufacturers of metal components

- Metal transformation sector

- Oil & gas sector

- Construction sector

- Manufacturers of components for the aeronautical, railway and automotive sectors

- Design and maintenance engineering firms

- Infrastructure

Certifications and Accreditations

Laboratory certified in ISO 9001 and ISO 17025 (ENAC certification No. 4/LE063)

ENAC ILAC accreditation for the construction sector in compliance with ISO 17025, under file No. 4/LE024

ENAC ILAC accreditation for acoustics in compliance with ISO 17025, under file No. 4/LE456. Laboratory with certified management system in accordance with standard UNE-EN 9100:2010.

AIRBUS authorised Laboratory for surface treatments

European Space Agency (ESA) authorised laboratory

Nadcap accreditation for chemical processes