News

Technological solutions for a smart city model

News

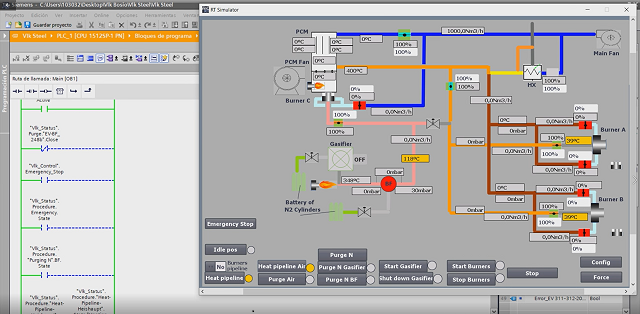

We validate the procedures that control these solutions in a Siemens PLC using the “S7-PLCSim Advanced” simulation tool

Different technologies were implemented to improve energy and environmental efficiency in industrial furnaces, which were heated by natural gas and heat recovery with conventional exchangers; both in the ceramic (TORRECID/Spain) and steel (BOSIO & VALJI/Slovenia) sectors.

Some of these solutions involve new refractory materials, heat recovery based on PCM (Phase Change Material), alternative fuel from a gasification process (syngas), improvements in monitoring and controlling new features, and a holistic tool application.

Our main achievement has been the validation and implementation of the procedures that control the new solutions for two types of industrial furnaces - pre-heating and melting. These procedures could be extended to other types of furnaces, thus increasing the potential users.

In addition to studying the feasibility of applying metaheuristic algorithms to increase efficiency in process control, we integrated improvements into monitoring and controlling the new solutions.

The procedures that control the new solutions have been validated in a Siemens PLC using the “S7-PLCSim Advanced” simulation tool, before being downloaded to the PLC itself, using the tools integrated in the STEP7 Professional TIA Portal. This tool was useful in reducing implementation times at the pilot plant and in graphically demonstrating the work done at the meeting to the European Commission evaluators.

* HMI developed to control the process of heat input by syngas and heat recovery through PCM, with the application implemented in the PLC in the background

These achievements were obtained as part of the European project VULKANO Novel integrated refurbishment solution as a key path towards creating eco-efficient and competitive furnaces.

Further information: