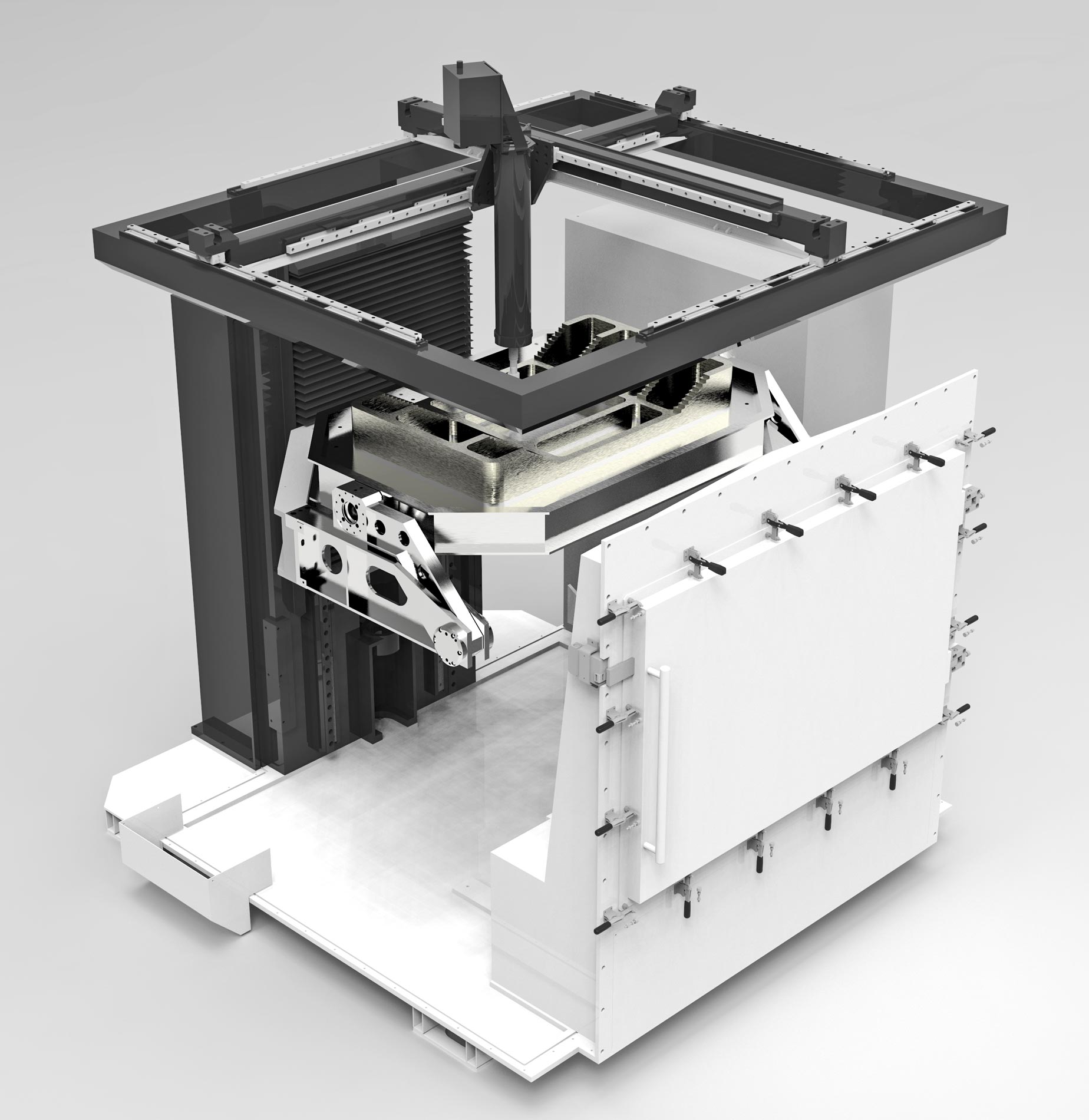

Machine for additive manufacturing by plasma and wire that makes it possible to manufacture large parts in both steel and titanium.

It has a build chamber that ensures a controlled argon atmosphere with a very low PPM level of oxygen and includes several online monitoring systems that ensure and control that material is deposited correctly.

Description

It is a machine for manufacturing metal components, using WAAM technology, with the following characteristics:

- Dimensions: 2,850 x 3,100 x 3,550 mm.

- Maximum part size: 1,300 x 900 x 500 mm.

- Maximum part weight: 300 kg

- Scalable up to 5 m parts.

- TILT axis. Input on both sides.

- Arc technologies:

- EWM cold and hot wire plasma welding

- EWM forceTIG cold and hot wire welding

- Inert atmosphere chamber (Ar, He or mixtures).

- Loading/unloading system. Maintenance of inert atmosphere.

- Input rates:

- Steel: up to 5 kg/h.

- Ti6Al4V: up to 3 kg/h.

- Inconel® 718: up to 4 kg/h.

Aimed at:

- Metalworking sector.

- Product developers, manufacturers of machinery, equipment and components

- Industrial service providers (control, programming/software, design, simulation and calculation)

- End users.