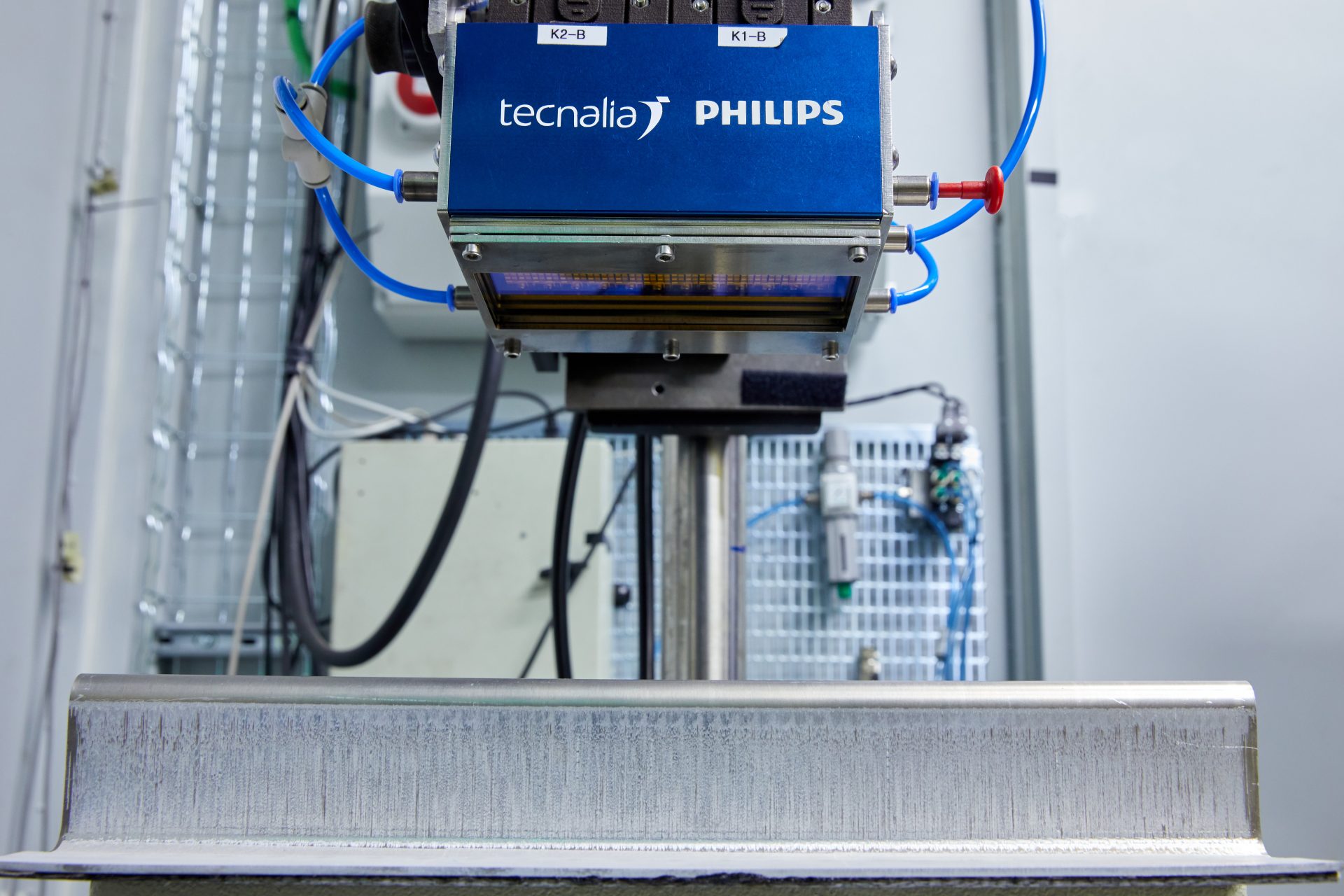

Laboratory with a VCSEL laser system, which is ideal for general heat treatment, welding and forming of plastics, surface coatings, surface stripping and drying and curing of coatings

Location

Description

The laboratory has a VCSEL laser system with 24 independent arrays, with a radiation surface of 104 x 40 mm2, which has the following characteristics:

- Heating of large surfaces without the need for scanning.

- Very similar wavelength to traditional diode lasers.

- Very precise control of the target temperature, without fluctuations.

- High flexibility when configuring temperature maps through dynamic and independent control of the VCSEL channels.

- Spatial control of temperature distribution on the surface.

- Temporal control of the temperature evolution at each point.

- Power densities of 100 W/cm2 and high processing speed.

- Compact, modular equipment for covering different surfaces.

- Lower cost than conventional laser systems.

Aimed at:

VCSEL laser technology can be applied in companies that are active in the following fields:

- Surface heat treatment.

- Welding and forming plastics.

- Applying coatings on surfaces.

- Stripping surfaces.

- Drying and curing coatings.

- Selective metal treatment.