Laboratory specialised in performing static and dynamic mechanical tests, both at room temperature and at high and low temperatures, on materials and components in order to ensure their quality and durability.

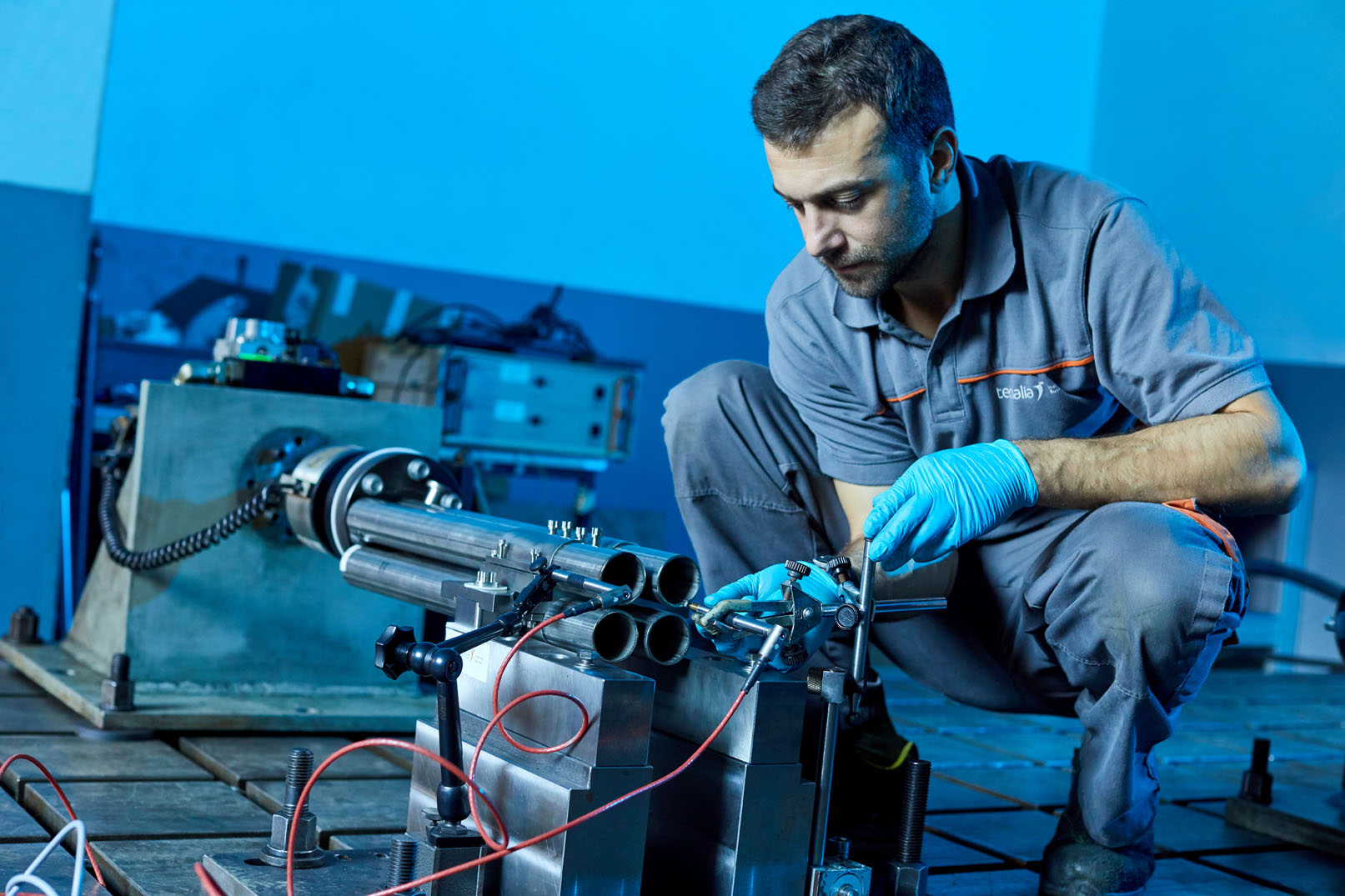

Our team of professionals has extensive experience in the mechanical field, which allows us to offer precise and reliable solutions adapted to your needs. We also have our own workshop for machining test pieces and tooling.

Description

The laboratory makes it possible to carry out tests on metallic materials, plastics, composites, adhesive joints and welded joints.

The main tests are as follows:

- Traction / compression tests at room temperature in chambers (from -70 ºC to +300 ºC) and in furnaces (<1,100 ºC).

- Brinell / Rockwell / Shore hardness tests.

- Folding and doubling tests at 3 and 4 points (-70 ºC to 300 ºC).

- Fracture mechanics (CTOD, KIC, J, GIC, GIIC) and crack growth (da/dN) tests.

- Fatigue test: axial (LCF, HCF, resonant up to 250 Hz), rotary and multi-axial bending

- Creep/stress rupture test.

- Charpy impact test (300 ºC to -196 ºC).

- Deformation monitoring using an extensometer.

- Shearing tests: in plane, out-of-plane, interlaminar and adhesive bond overlap.

- Iosipescu test.

- Mode I and Mode II interlaminar fracture test.

We design customised tests for components: Railway sector components (rails, connectors, clips, lag screws…), electrical substation connectors, photovoltaic panel structures, medical devices (prostheses, syringes…), submarine cables, lift cable ties, metal chains for conveyor machines, hooks for aerospace coupling, engine parts (exhaust rocker arm)….

The equipment available is:

- Universal testing machines (50 N to 1000 kN).

- Rockwell, Brinell and Shore durometers.

- Impact drop towers and pendulums.

- Environmental chambers (-70 ºC to 300 ºC) and furnaces (<1100 ºC) for universal testing machines.

- Rotary bending fatigue and resonance fatigue testing equipment.

- Creep testing machines.

- Multi-axial test bench with 3 actuators (10, 50, 100 kN).

We have our own tool and test specimen machining workshop, which allows us to ensure the traceability and reliability of our results and reduce delivery times. We include the preparation of samples with adhesive bonds with the application of curing / post-curing cycles.

Aimed at:

- Renewable energies

- Manufacturers of metal components

- Metal transformation sector

- Oil & gas sector

- Construction sector

- Manufacturers of components for the aeronautical, railway and automotive sectors

- Design and maintenance engineering firmsInfrastructure

Certifications and Accreditations

Laboratory certified in ISO 9001 and ISO 17025 (ENAC certification No. 4/LE063)