The VIPRISCAR initiative shows the feasibility of manufacturing industrial coatings, hot-melt adhesives and biomedicine products from renewable sources

The bioeconomy, or economy resulting from the use of renewable biological resources to obtain added-value products, has become a key concept for sustainable development. It helps tackle some of society’s challenges and reduces the use of fossil fuels and non-renewable raw materials.

A group of European companies and research centres are working together on the VIPRISCAR initiative in order to validate a highly efficient process dedicated to large-scale production, from raw materials of a chemical compound with a wide range of applications: the isosorbide bis(methyl carbonate) (IBMC).

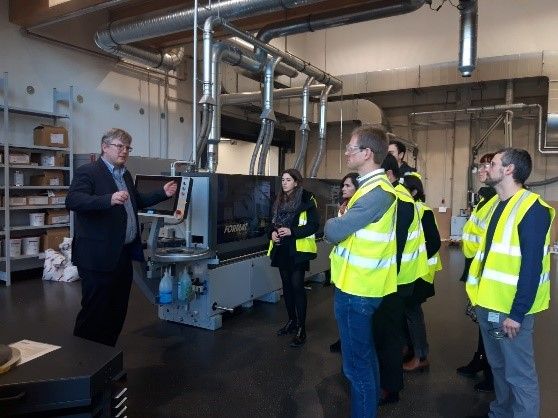

In a recent meeting held at the JOWAT facilities, the participating consortium expressed its satisfaction with the progress and results obtained.

VIPRISCAR combines reaction and purification processes that make it possible to obtain IBMC of various purity grades, achieving up to 99%. One 200L pilot plant is producing the first batches of IBMC, covering the 100 kg for next May.

Similarly, production of polymers from IBMC has begun. The optimised pre-polymers will be used for coatings in the automotive and furniture industries, hot-melt adhesives and catheters for biomedical applications.

Further information

Press release on the consortium meeting.

![]()

This project has received funding from the Bio-based Industries Joint Undertaking (JU) under the European Union H2020 research and innovation programme in accordance with Grant No. 790440. The JU is supported by the H2020 EU Research and Innovation programme and the Bio-based Industries Consortium