News

News

13 November 2018

It is a secure and agile technological solution for the remote handling of mechanical parts that increases process productivity

The objective of the INL sample preparation laboratory, leader in the United States in the research of radioactive materials, is to achieve a safe and agile solution that increases the productivity of its operations.

Currently such operations are carried out remotely (to protect the operator), with mechanical manipulators that are difficult to control, not very intuitive and have limited capacity to guide and move parts between different spaces and tests.

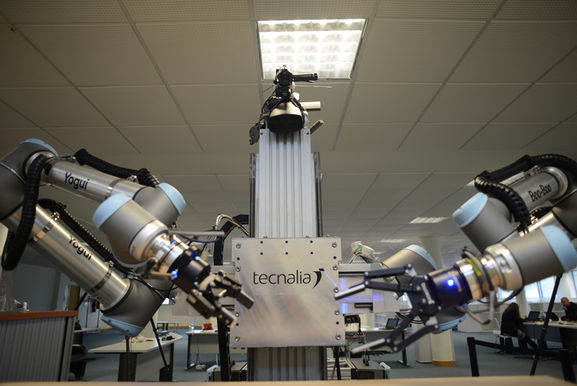

The INL team has designed an innovative and profitable robotic solution that provides the operator with greater skill during the remote operation. With the new system, remotely controlled robots faithfully repeat the movements of the operator’s hands, so that handling is more accurate, safer and more intuitive. As a result, it is expected that the remote handling of parts of radiation material will be faster and more effective, leading to increased plant performance.

The system is designed for automatic and remote operation. In the first system, robots in the radiation environment have the capacity to carry out automatic part pick up, movement and set down operations, based on the artificial vision system that they include. In the second system, a technician inside the protected cell controls the movements of the robot arms in real time via specialised joysticks that can transmit the force that the robot is applying to the objects inside the radiation area to the operator's hands. The transmission of force during this process guarantees intuitive interaction between the robots and the objects being handled.