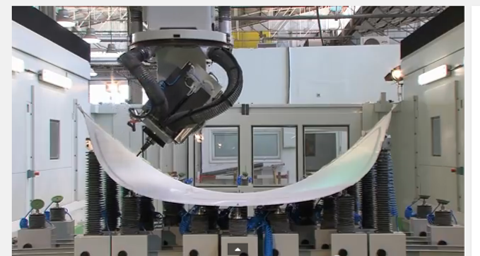

Flexible machining system that allows for the milling of skin type parts within the tolerances required by industry and significantly reducing the investment in equipment.

This innovative concept is based on the use of a universal tooling combined with a development that is able to adapt the path of the tool for the proper machining of the parts. The flexible tooling can be adapted to the required geometry, uniformly securing the entire surface of panels.

The integration of both innovative devices enables a wide variety of low rigidity panels to be machined, including different sizes, geometries and curves. Furthermore, this system enables work to be carried out, interlayering milling, drilling and even edging phases and hence optimising the fine-tuning phase.

This technology enables the investment in equipment for the machining of skin panels to be drastically reduced.

This project has received funding from the European Union’s Horizon 2020 Research and Innovation programme, under Grant Agreement No. 213371.