We offer non-fusion additive manufacturing services for high precision components using powder metallurgy technologies: metal, intermetallic, cermet and advanced ceramic components.

We are equipped to adapt powder (raw material) in early stages, as well as in post-processing: debinding, sintering or heat treatments.

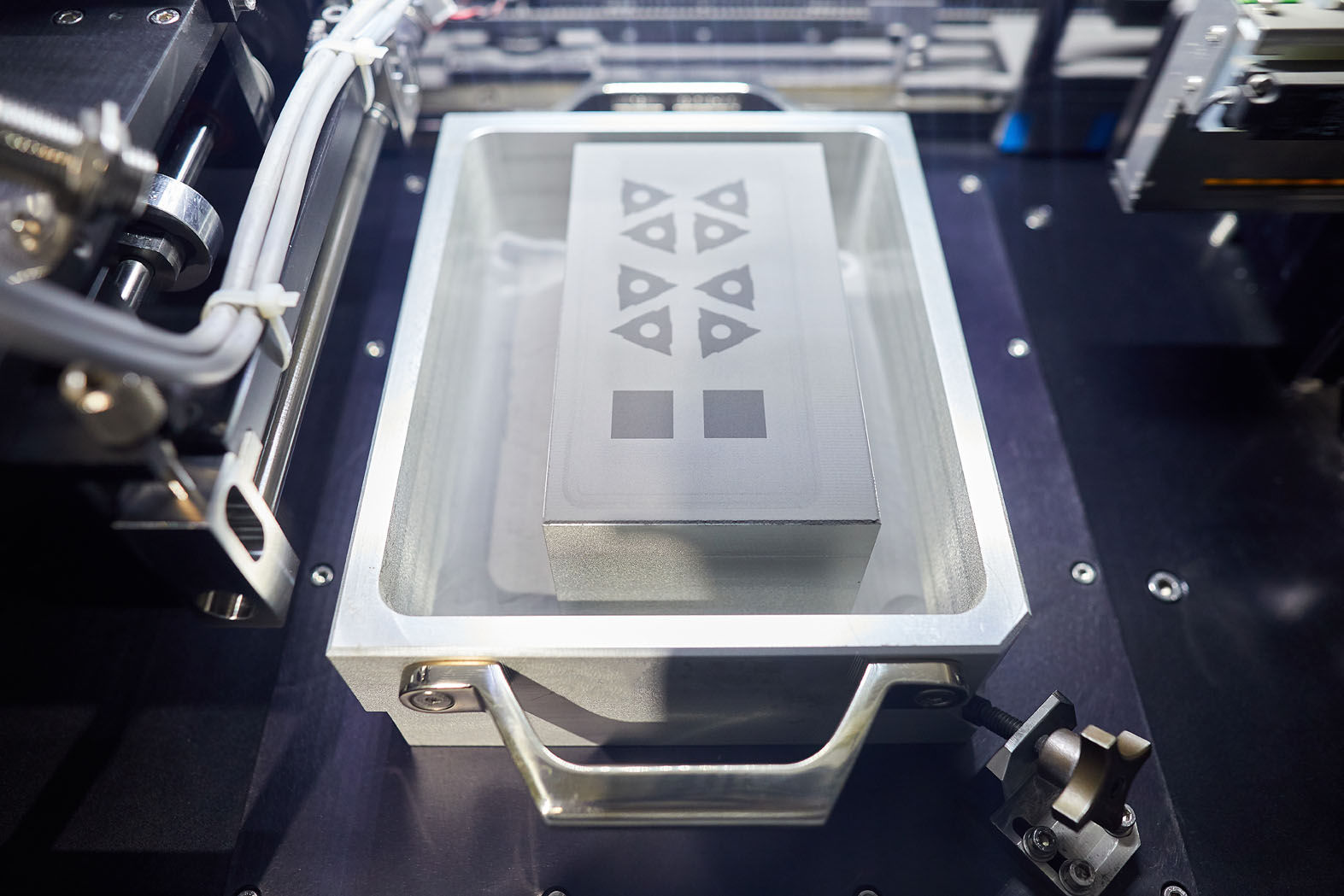

Powder metallurgy technologies are processes that enable parts at practically final dimensions to be obtained. In addition to being an alternative in order to obtain final dimension parts, the Binder Jetting process permits designs that increase the functionality of the components.

Through this process, we can process metal materials, ceramics and their mixtures (metal matrix composites, cermets, ceramic matrix composites, etc.)

We work on the whole process chain at our laboratory: redesign of the part, adaptation of the raw material, printing, sintering of the part and subsequent treatments (heat treatments, coatings, etc.). We also assess and validate the parts obtained.

Aimed at:

- Manufacturers of components for the aeronautical and space sector, iron and steel industry, energy, automotive, metal mechanic mechanical-industry capital goods, chemical, petrochemical, biorefinery and railway sectors.