We offer asset sensing and monitoring services to optimise their management.

Advances in the field of sensing, communication, data storage and calculation capabilities enable maintenance asset management tasks to be optimised.

Companies are increasingly opting for predictive or prescriptive approaches which are possible thanks to sensors and data analytics.

We provide different sensing and monitoring solutions to optimise asset management.

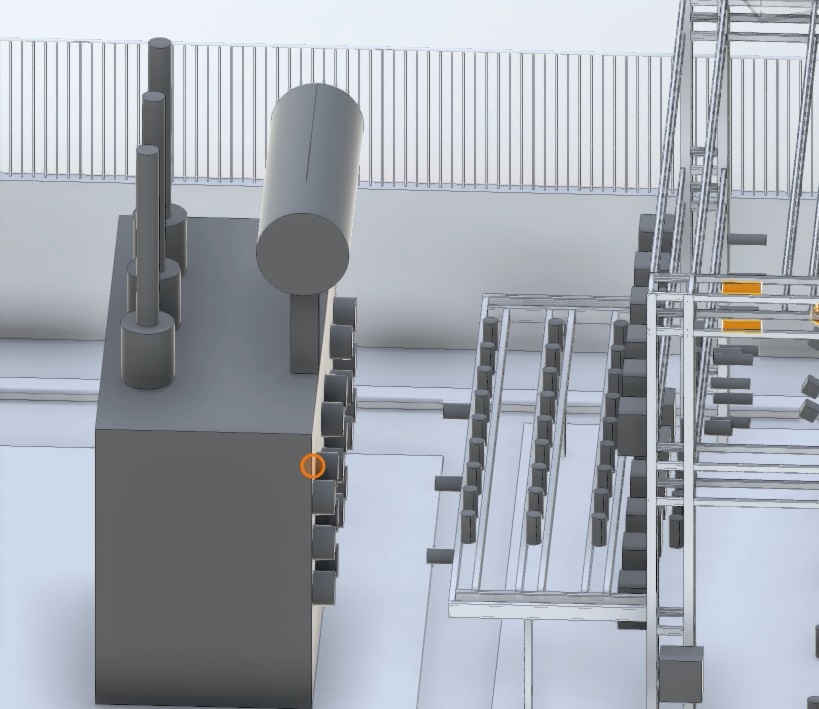

Sensing consists of the installation of sensors and connectivity devices in different components of the managed asset. The machine to machine (M2M) data is subsequently processed to obtain a wide range of applications, among which process simulation or components performance stand out. This enables its future status to be predicted and this information to be used to manage the asset predictively.

Monitoring consists of the installation of laser measuring devices and their configuration in order to collect spatial data from certain points of the managed asset at determined intervals. This information is subsequently processed and used to understand the performance of the asset over a certain period of time, among other things.

The most noteworthy benefits of this service are:

- Constant monitoring: 24 hours/day + 365 days/year.

- High quality images.

- High sampling frequency.

- Pinpoint accuracy (1mm +1/-0.5).

- Remote measurement, without affecting traffic or production.

- Staff do not need to be in the workplace.

- Cost-effective.

Aimed at:

- Facilities Operators

- Facilities Owners

- Engineering Firms