Robotic solution for automation of orbital joints in fuselage panels, including drilling, sealant application and blind rivet installation processes, as well as an computer reference system. This innovative automation system significantly improves production in assembly stages, saving time and reducing process costs.

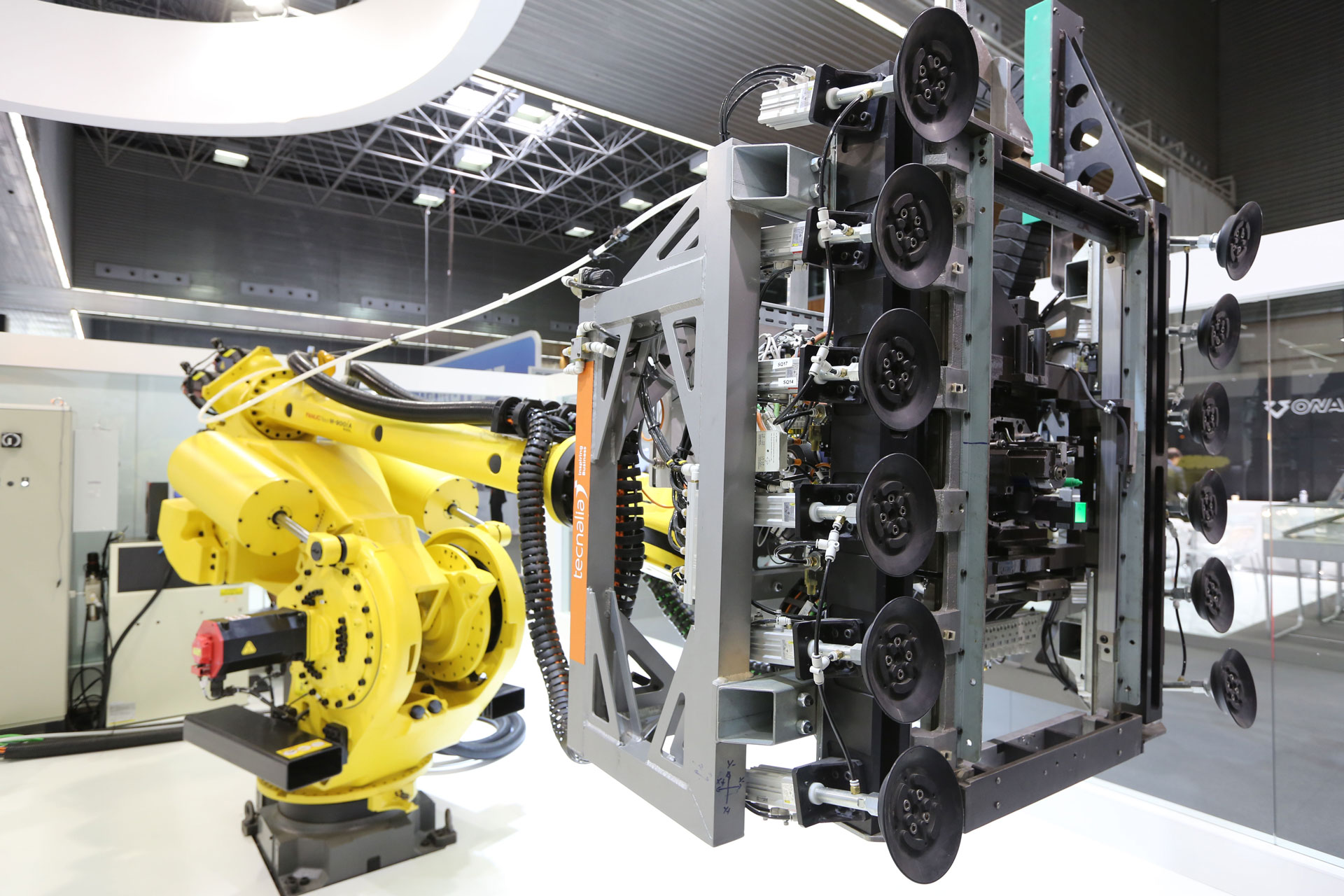

The assembly of aeronautical fuselage panels and sections is still very much a manual process today. Under this project, we have conceptualised, developed and validated an innovative solution for flexible automation that consists of an industrial robot that carries a 4-axis CNC machine as an end-effector, which is secured to the fuselage using vacuum suckers and carries out drilling, countersinking, sealant application and blind rivet installation processes in discreet areas of the fuselage.

The robot positions the system on the fuselage with the precision limited to its features, and the vision system integrated in the end-effector enables the required precision to be reached for the positioning related to the piece, with a unique reference system for the entire work window.

This project has received funding from the European Union’s Horizon 2020 Research and Innovation programme, under Grant Agreement No. 213371