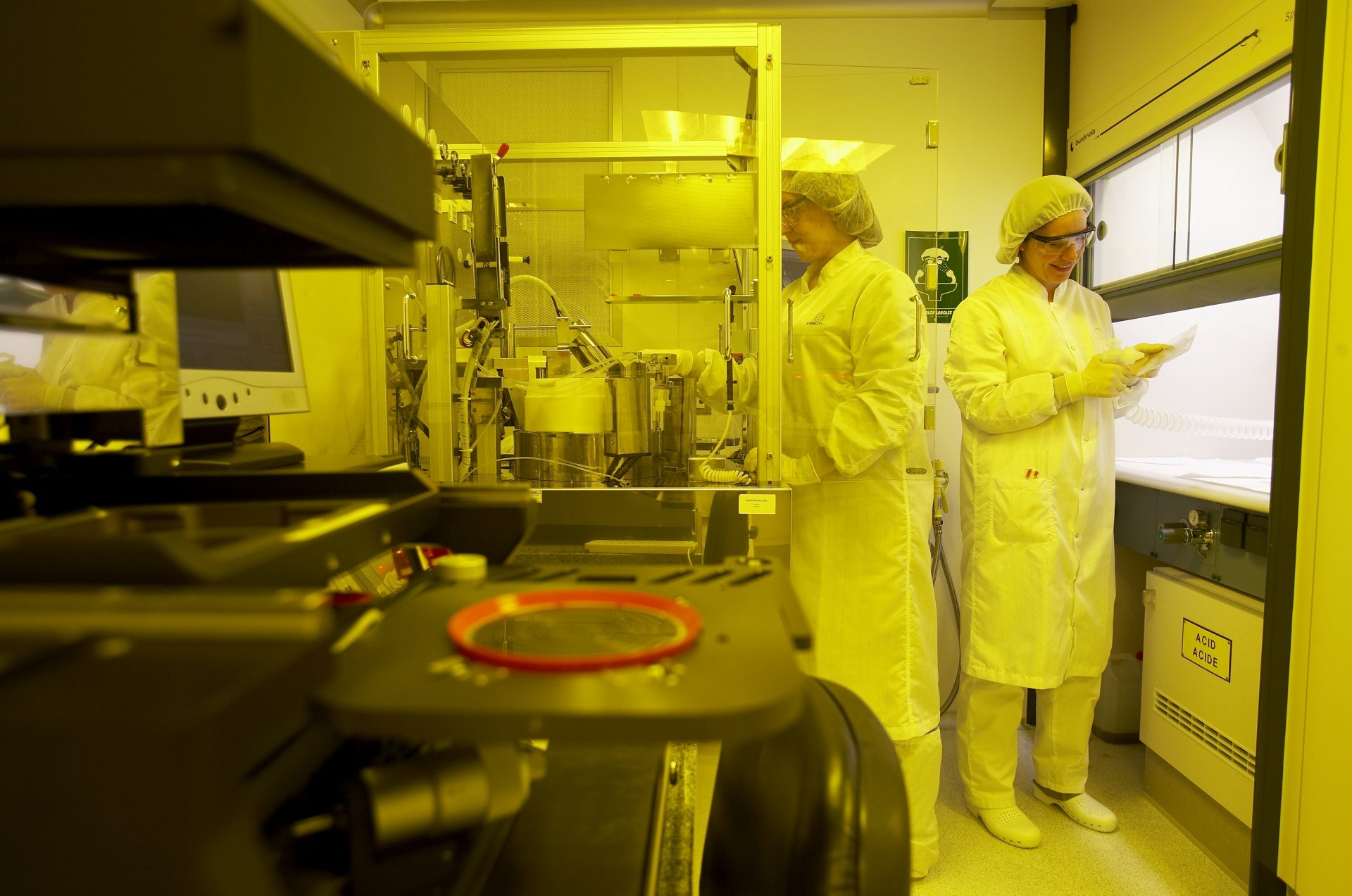

Laboratories with a low level of particle contamination in the air where the temperature, relative humidity, differential pressure and other environmental parameters are within specific limits.

Clean rooms are subdivided into changing rooms, and areas for handling nanomaterials and micro-nanomanufacturing. They comply with ISO 14644, which is equivalent to ISO class 8, in accordance with USA Federal Standard 209 D.

Description

Environmental conditions of clean rooms:

- The limit of particles equal to or greater than 0.5 microns is 100,000 and the limit for particles of 5 microns is 700 per ft3 of air.

- Average temperature of 21 ºC ± 3 ºC.

- Over-pressurised rooms compared to the outside with a minimum positive pressure difference between adjacent rooms of 12 Pa.

- Minimum recirculation flow rates/hour = 20 R/h.

The rooms are subdivided into different areas:

- Room for handling nanomaterials: for preparation, cleaning, functionalisation and handling. It consists of 2 fume cupboards and equipment for dispersing nanomaterials: ultrasound, Dispermat bead mill, mechanical stirrers…

- Photolithography room: it has a spin-spray coater for depositing thin films of polymers, photosensitive resins, epoxies, etc., and a photolithography machine, microcontact printer and UV-nanoimprint equipment. Fume cupboard for handling solvents. Optical microscope with polarised light.

- Versatile room that can be tailored to suit needs. Equipment available: plasma etcher, incubators, MALS detector. There is also a fume cupboard.

The rooms have general services such as:

- Availability of ultra-pure quality water at different points in the rooms.

- Compressed air usage points.

- Ar and N2 usage points.

Aimed at:

- Industrial companies where manufacturing processes require enclosures with a controlled atmosphere to ensure clean working conditions.