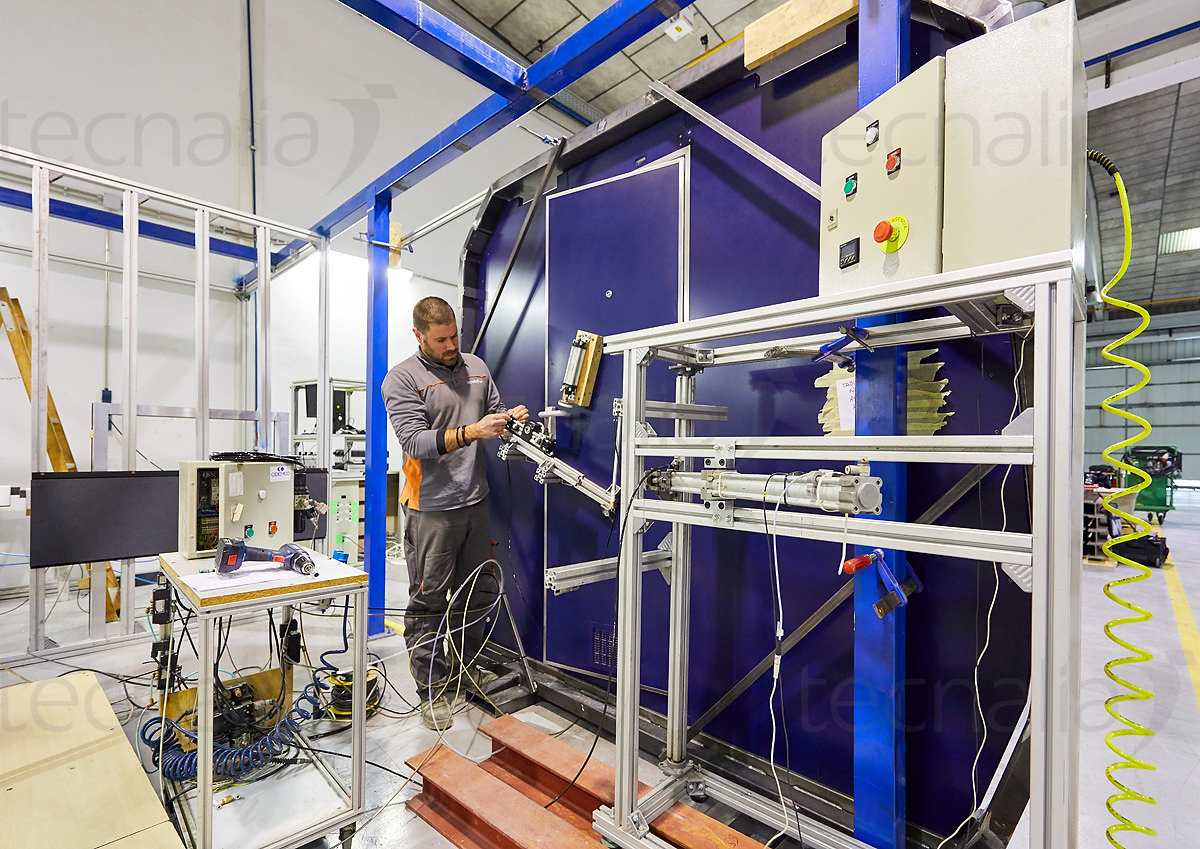

We provide testing, certification, product development and engineering services for the transport sector.

For this purpose, we have a network of multi-disciplinary laboratories.

Tested Products

- Rolling stock

- Bogies

- Springs

- Axles

- Building hardware

- Seats

- Floors and ceilings

- Windows and enclosures

- Panels

- Access, escape and automatic doors, etc.

- Loads on vehicle bodies and components

- Floor panels and plywood

- Glass elements.

- WC modules.

- Electronic components.

- Driving consoles and desks, external front and end carriages, cowlings.

Materials Assessed

- Metal materials (steels, castings, aluminium alloys, copper, nickel, titanium, etc.)

- Plastics and composites

- Paints and coatings

- Adhesives and sealants

- Welding

- Ceramic materials

- Glass

- Plywood panels, etc.

Type of Tests

- Mechanical and durability in use tests

- Chemical analysis

- Reaction and resistance to fire tests

- Metallographic analysis, microanalysis and electron microscopy

- Vibration tests

- Acoustic tests

- Optical characterisation

- Thermal-environmental tests:Environmental ageing and corrosion.

- Electrical and EMC tests

- Analysis and diagnosis of “non-conformities”.

- Inverse engineering.

- Review and design of product and process specifications.

- Failure analysis and prevention (RCA).

- Selection of materials

- Predictive maintenance.

- Capturing geometric reality.

- 3D digitalisation

- Electrical Tests

Aimed at:

- Manufacturers of components (furniture, panels, doors, wheels, windows, partitions, hardware, electronic equipment, etc.) for the automotive, aeronautical and railway sectors.

Accreditations and Recognition

Laboratory certified in ISO 9001 and ISO 17025 (ENAC certification No. 4/LE063)

AIRBUS authorised Laboratory for surface treatments

European Space Agency (ESA) authorised laboratory

Nadcap accreditation for chemical processes

Nadcap accreditation for material testing